1. 正確な温度制御、パーソナライズされた快適な体験

の 新エネルギー電子制御空冷システム は、高度な電子制御技術により、従来のエアコンの単一温度設定モードをはるかに超えた、室内温度の微妙な制御を実現します。システムに内蔵されたインテリジェントセンサーは、室内の温度、湿度、人間の活動、その他のパラメーターをリアルタイムで監視し、複雑なアルゴリズム分析を通じて現在の環境と人間の知覚に最適な温度に自動的に調整します。このパーソナライズされた温度制御戦略は、過度の温度差によって引き起こされる不快感を回避するだけでなく、一定の温度環境に長時間置かれることによって引き起こされる可能性がある「空調病」などの健康問題を効果的に防止します。さらに、ユーザーは携帯電話アプリを通じて、いつでもどこでも自宅の温度を遠隔制御することもでき、究極の利便性と快適さを享受できます。

2. 高効率・省エネでエネルギー消費コストを削減

の high efficiency and energy consumption characteristics of the new energy vehicle electronic control system and air cooling system provide a powerful reference for the application of new energy electronic temperature controlled air cooling system in the home field. The system adopts advanced frequency conversion technology and energy efficiency optimization algorithm, which can automatically adjust the operating speed of the compressor and fan according to the indoor load to avoid unnecessary energy waste. During the cooling or heating process, the system can accurately control the input and output of energy to ensure that every bit of energy can be fully utilized. This energy-efficient design not only reduces household energy expenses, but also reduces the impact on the environment, which is in line with modern families' pursuit of green and low-carbon life.

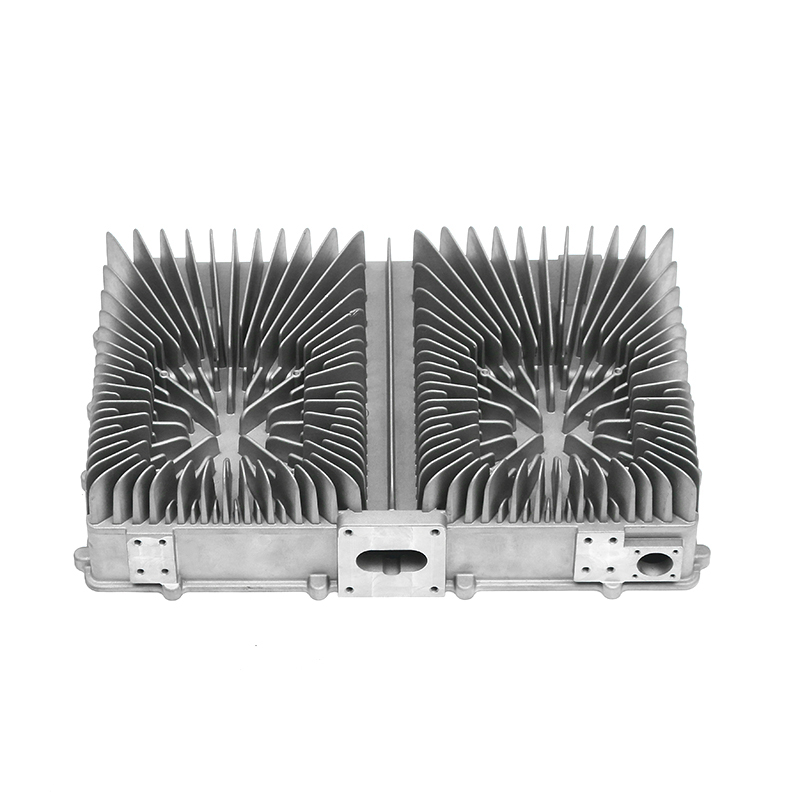

3. 多様なニーズに応えるカスタマイズ金型

の high customization requirements of the electric control air cooling system of new energy vehicles have promoted the continuous advancement of mold manufacturing technology. Similarly, the application of new energy electric control air cooling series molds in the home field also shows strong customization capabilities. Mold manufacturers can tailor suitable air cooling system molds according to the specific needs of customers and the actual conditions of the home environment. Whether it is wall-mounted, cabinet-type or embedded installation, whether it is simple style, retro style or modern technology-filled appearance design, it can be met. This highly customized service not only enhances the overall beauty and personalization of the home, but also ensures the perfect integration of the air cooling system and the home environment.

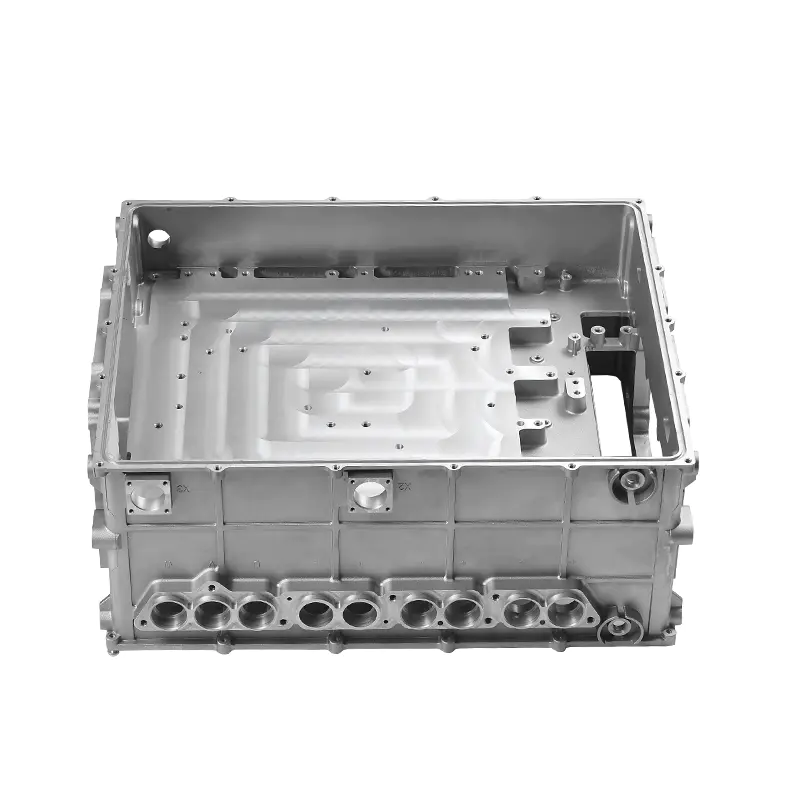

4. 安定した品質を実現する精密加工

新エネルギー電気制御空冷シリーズ金型の設計・加工工程には、最先端のCAD/CAM技術と高精度加工設備が使用されています。これらのハイテク手段の適用により、金型製造プロセスがより正確かつ効率的に行われます。 3D モデリングとシミュレーションを通じて、設計者はコンピュータ上で金型の予備設計と最適化調整を完了でき、従来の手動設計に存在する可能性のあるエラーや欠陥を回避できます。同時に、高精度の加工装置により、金型の各コンポーネントが極めて高い寸法精度と表面品質を確実に達成し、射出成形やダイカストなどの後続の成形プロセスに強固な基盤を提供します。この精密加工技術の適用により、金型の品質安定性が向上するだけでなく、使用中の空冷システムも優れた性能を維持できます。

5.耐久性と安定性があり、耐用年数が延長されます。

の new energy electric control air cooling series molds have also made great efforts in material selection and process application. The mold manufacturer selected high-quality steel, alloy and other wear-resistant, high temperature resistant and corrosion-resistant materials as the main components of the mold. These materials not only have good mechanical properties and processing properties, but also can maintain stable physical and chemical properties during long-term use. In addition, advanced heat treatment, surface treatment and other process methods are also used in the mold processing process to further improve the hardness and wear resistance of the mold. The combined effect of these measures enables the new energy electric control air cooling series molds to resist the test of various harsh environments and complex working conditions during use, maintaining stable performance output and a long service life. This not only reduces the frequency and cost of mold replacement, but also provides users with a more reliable and durable air cooling system product.